Difference between revisions of "Laser propulsion"

| Line 3: | Line 3: | ||

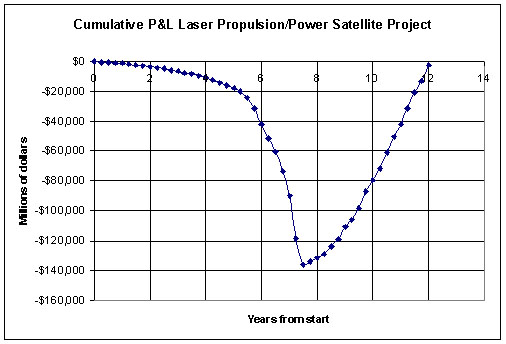

This rough model uses bootstrapping to build 3.5 GW of propulsion lasers powered from a power sat built only to power the lasers. Years are horizontal, millions on the vertical axis. The peak investment is a bit short of $140 B. | This rough model uses bootstrapping to build 3.5 GW of propulsion lasers powered from a power sat built only to power the lasers. Years are horizontal, millions on the vertical axis. The peak investment is a bit short of $140 B. | ||

| − | Power_sat_PandL.jpg | + | [[File:Power_sat_PandL.jpg]] |

This is a financial model for a power sat construction business using very large and expensive lasers to power Skylon derived vehicles to lift parts for power sats. By the 12 year mark, the project has built 69 five GW power sats and paid back the initial investment from profit on sales ($1.6 B/GW including the rectenna—low enough to sell power at 2 cents per kWh). The massive plunge in the curve comes from installing $25 B of lasers in the last quarter of the buildup just before starting to sell power sats. The original 300-ton regular Skylons deliver 6 tons of parts to GEO per flight. As more and more laser power comes on line, the payload climbs from 2% of takeoff mass to 15% (18 tons of a 120 ton vehicle). Flight rate ramps up to 72 per day on a production rate of 3 Skylons per month. (144 vehicles flown every other day, it takes 3 per month to compensate for ones retired after ~500 flights.) | This is a financial model for a power sat construction business using very large and expensive lasers to power Skylon derived vehicles to lift parts for power sats. By the 12 year mark, the project has built 69 five GW power sats and paid back the initial investment from profit on sales ($1.6 B/GW including the rectenna—low enough to sell power at 2 cents per kWh). The massive plunge in the curve comes from installing $25 B of lasers in the last quarter of the buildup just before starting to sell power sats. The original 300-ton regular Skylons deliver 6 tons of parts to GEO per flight. As more and more laser power comes on line, the payload climbs from 2% of takeoff mass to 15% (18 tons of a 120 ton vehicle). Flight rate ramps up to 72 per day on a production rate of 3 Skylons per month. (144 vehicles flown every other day, it takes 3 per month to compensate for ones retired after ~500 flights.) | ||

Reducing the cost of the lasers (plus optics, power supply and heat sink) figured at $20,000 per kW or reducing the amount of laser required would decrease the peak financing. We also might be able to spread out the last lasers past initial revenue. | Reducing the cost of the lasers (plus optics, power supply and heat sink) figured at $20,000 per kW or reducing the amount of laser required would decrease the peak financing. We also might be able to spread out the last lasers past initial revenue. | ||

Revision as of 16:04, 29 June 2012

Laser propulsion to build power sats, first cut.

This rough model uses bootstrapping to build 3.5 GW of propulsion lasers powered from a power sat built only to power the lasers. Years are horizontal, millions on the vertical axis. The peak investment is a bit short of $140 B.

This is a financial model for a power sat construction business using very large and expensive lasers to power Skylon derived vehicles to lift parts for power sats. By the 12 year mark, the project has built 69 five GW power sats and paid back the initial investment from profit on sales ($1.6 B/GW including the rectenna—low enough to sell power at 2 cents per kWh). The massive plunge in the curve comes from installing $25 B of lasers in the last quarter of the buildup just before starting to sell power sats. The original 300-ton regular Skylons deliver 6 tons of parts to GEO per flight. As more and more laser power comes on line, the payload climbs from 2% of takeoff mass to 15% (18 tons of a 120 ton vehicle). Flight rate ramps up to 72 per day on a production rate of 3 Skylons per month. (144 vehicles flown every other day, it takes 3 per month to compensate for ones retired after ~500 flights.)

Reducing the cost of the lasers (plus optics, power supply and heat sink) figured at $20,000 per kW or reducing the amount of laser required would decrease the peak financing. We also might be able to spread out the last lasers past initial revenue.